How to replace Gear Stick Balll

When the Imp was

new one thing it was praised for was the

directness and slickness of the gear change

"like a big switch", however over

time the gear stick pivot 'gear ball' which

is made of hard rubber and steel wears away

and you are left with a sloppy feeling gear

stick. It also makes the gear change poor...

So what can be done? Well a replacement

'gear ball' made from nylon is available for

Imp Club Spares and other Imp Specialists

for about a £5 - but how do you fit

it.....

Tools and

Supplies Required

Hammer, 4.5mm Drill Bit, 6mm (1/4")

Drill Bit, Centre Punch,Pop Rivet Gun, 4x

4mm (5/32") pop rivets, Molygrease,

Drill

- Remove the carpet, rubber matting in

order to get access to the bottom of the

gear stick.

Remove the rubber gaiter fig 1

Fig 1

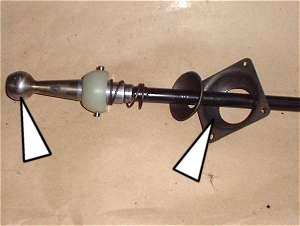

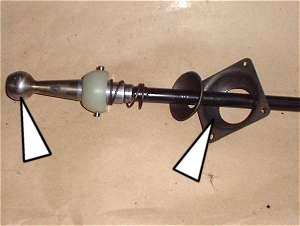

- Centre

punch each of the 4x rivets as arrowed

(fig 2), try to be accurate and punch

the middle of the rivet heads, it will

help lots with the next operation

Fig 2

- Using the

6mm (1/4") drill, drill off the just the

rivets heads (fig 3), DO NOT drill all

they way through! You are just

trying to remove the rivet heads, you

might need to chisel the remains of the

rivet head off after drilling..

Once you have done these use a punch to

knock the remains of the rivets though

the hole.

You can retrieve bits of rivets by

clambering under the car and once

removing the under tray, you can pull

the rubber boot of the bottom of the

gear stick assembly and pick out rivet

remains

Fig 3

- Once the

rivets have been removed the part

arrowed(fig 4) will spring up.

Fig 4

- As will

this part which is under it!

Fig 5

- You can

pull the gear stick up out of the car.

and give it a good clean!

Fig 6

- Erm well

there should be a rubber ball thing at

the end of the arrow! (fig7) The might

explain why the gear stick was a bit

sloppy!

Fig 7

- Put the

gear stick in the vice and knock the pin

out using a punch. You do not need that

metal ring (fig 8 ), but it is worth

putting it in the bottom of your toolbox

- it may come in handy for something one

day!

Fig 8

- This is

how the assembly should look once it is

finished (fig 9), but before the pin is

fitted.

Fig 9

- Use the

4.5mm dia drill (note this is slightly

smaller the existing hole in one side of

the new plastic gear ball and also the

pin).

You may have noticed that only one side

of the gear ball is drill, this is

normal. Assemble the new gear ball as

shown and line up the hole in the new

gear ball with the one in the gear

stick. Carefully (slowly) drill through

the assembly (fig 10) so as to drill

though the other side of the new gear

ball, it

is very important that you do this

carefully and also to use a drill bit

that is slightly smaller than the pin.

Fig 10

- Push the

pin through the new gear ball from the

side that had the existing hole towards

the hole that you have just drilled

I used a bit of loctite on the pin for

good measure. MAKE

sure the pin sticks out each side

evenly, and it is tight so it doesn't

fall out. (fig 11)

The red arrow points out the spring ball

which locates the gear stick in the gear

linkage. On this car this points towards

the engine. (the Haynes manual diagram

shows it being the other way! Put it

back the way you found it.)

Fig 11

- Grease

these areas well (white arrows on fig

12) with some moly grease. The ball

should be self lubricating, put it won't

hurt to put a small smear of grease on

it.

Fig 12

- Before you refit the gear stick assembly to the

car, wrap a piece of rag around a

screwdriver and poke it down through the

car and clean out the part of the car

that the new ball pivots in AND down in

the gear linkage that the bottom of the

gear stick connects with.

Refit the gear stick to the car,

remember which way that spring ball was

point as pointed out in point 11 above.

Make sure the pin is in it slots, pop a

bit of grease on the pin ends. The part

at the end of the arrow should have some

grease on it!

Fig 13

- You need

to push this bit down (fig 14), against

the spring.

Fig 14

- Whilst

holding it down slot in 4x 4mm (5/32")

pop rivets.Using a pop rivet gun (fig

15), fit this plate ensuring that plate

is pulled down properly If the rivets

snap before the plate is pulled down

properly then you need push down harder!

If the plate hasn't been pulled down

quite properly you can use a centre

punch to tighten them down by striking

the centre of the rivet heads.

Fig 15

Right that is it - you should now have a

slick positive feeling gear stick! Time for

a cuppa